- product description:

1. Fully automatic brick making machine frame: made of high-strength steel and special welding technology, strong and durable.

2. Fully automatic no-burning brick machine guide machinery: long guide design: German Igus special wear-resistant guide, special steel finely processed with chrome plating on the surface to make guide columns, which have good torsion resistance and wear resistance. The overall mechanism has accurate positioning accuracy and long service life.

3. Fully automatic brick-free brick machine distribution system: designed using storage material and cloth separation technology. The material receiving of the material box can be precisely controlled under the action of the forced arch breaking mechanism. Produces powerful centrifugal discharge to make the cloth evenly distributed quickly.

4. Fully automatic non-burning brick machine vibration system: adopts German technology: (integrated multi-point vibration system). Its frequency conversion control system can automatically change the vibration frequency and amplitude according to different production needs. It has the characteristics of strong vibration force, fast response speed and vibration point distribution, and can obtain ideal high-density products.

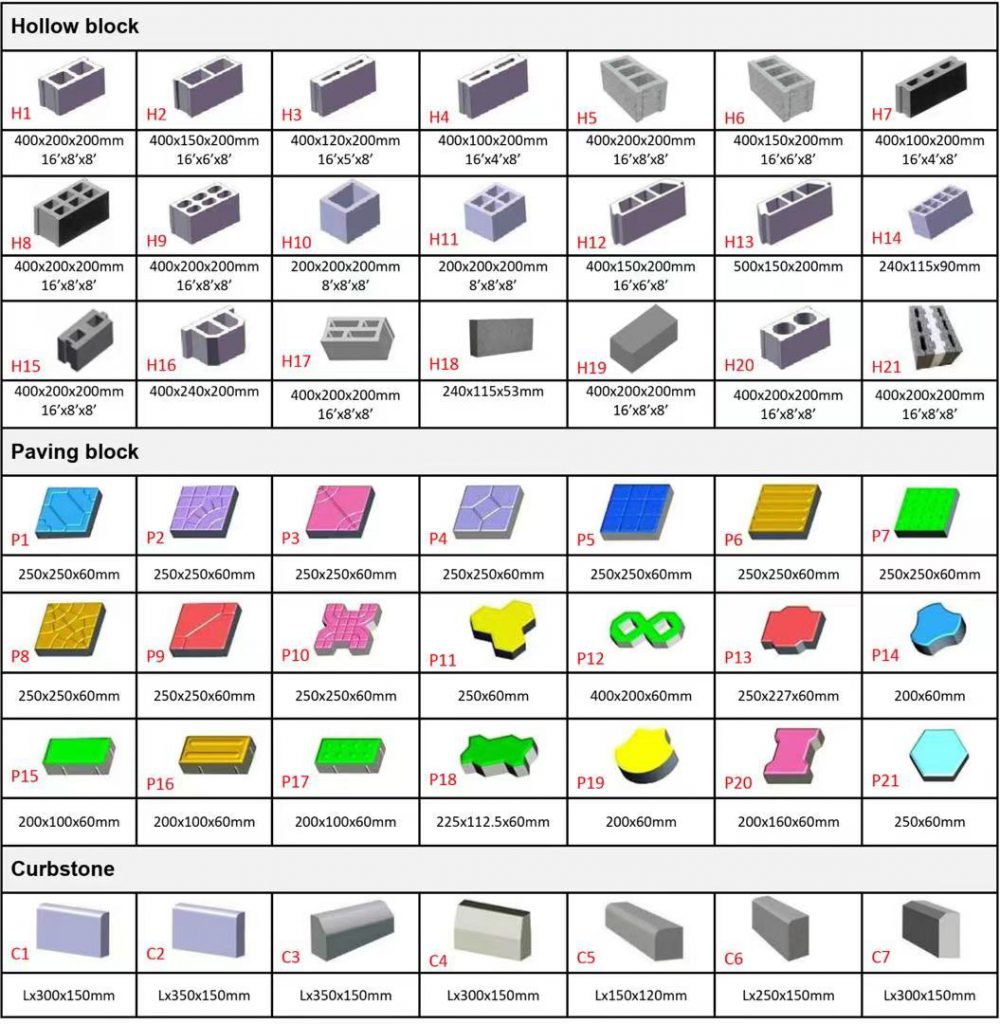

5. Fully automatic no-burning brick machine molded structure: specially designed molded structure, easy and convenient to replace the mold

6. Airbag vibration compensation device for fully automatic no-burning brick machine: The airbag compensation technology and device are used to make the vibration extremely ideal.

7. Fully automatic brick-free brick machine control system: computer control, human-machine interface. Electrical appliances are from well-known Japanese and German brands. The control system is designed and compiled based on 20 years of actual front-line production and design experience and development trends to meet national conditions. It can be operated without the need for professionals and requires only simple training. The powerful memory can be upgraded when needed.

- Block machine specifications:

| Dimension(L*W*H) | 5600×2200×1800mm | Moulding period | 15S |

| Hydraulic pressure | 26Mpa | Power | 72.7KW |

| Vibration force | 65KN | Vibration Frequency | Max.6000r/m |

| Weight | About 10T | Pallet size | 1300X900mm |

- Capacity reference:

| Size(LxWxH) mm | Pcs/Mould | Pcs/hr | Pcs/ 8Hr |

| 400X200X200 | 12 | 2880 | 23040 |

| 400X150X200 | 16 | 3840 | 307020 |

| 400X100X200 | 24 | 5760 | 46080 |

| 400x100x100 | 24 | 5760 | 46080 |

| 240X115X53 | 60 | 14400 | 115200 |

| 200x100x60 | 42 | 7560 | 60480 |

| 225×112.5X60 | 30 | 5400 | 34560 |