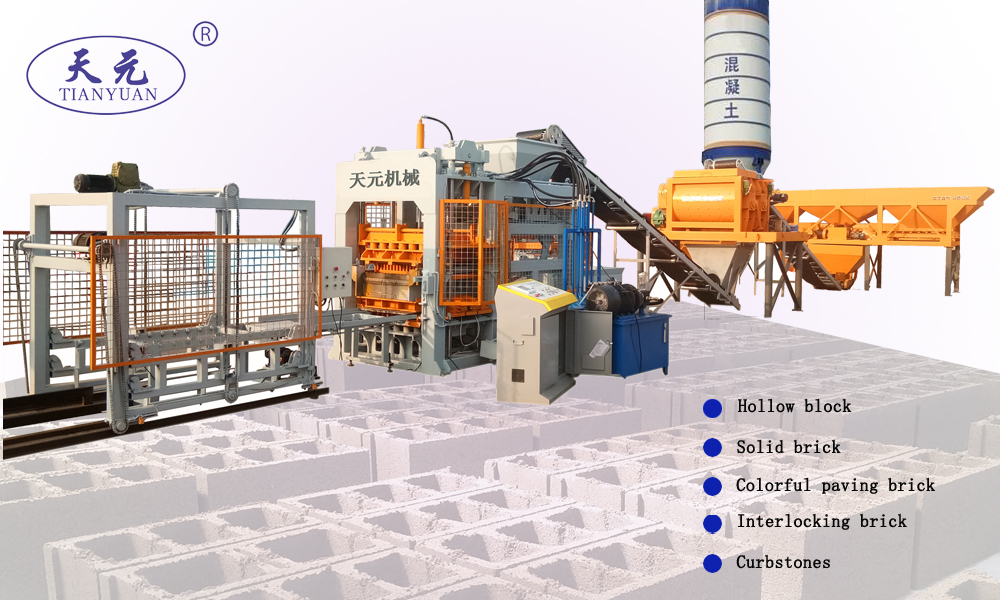

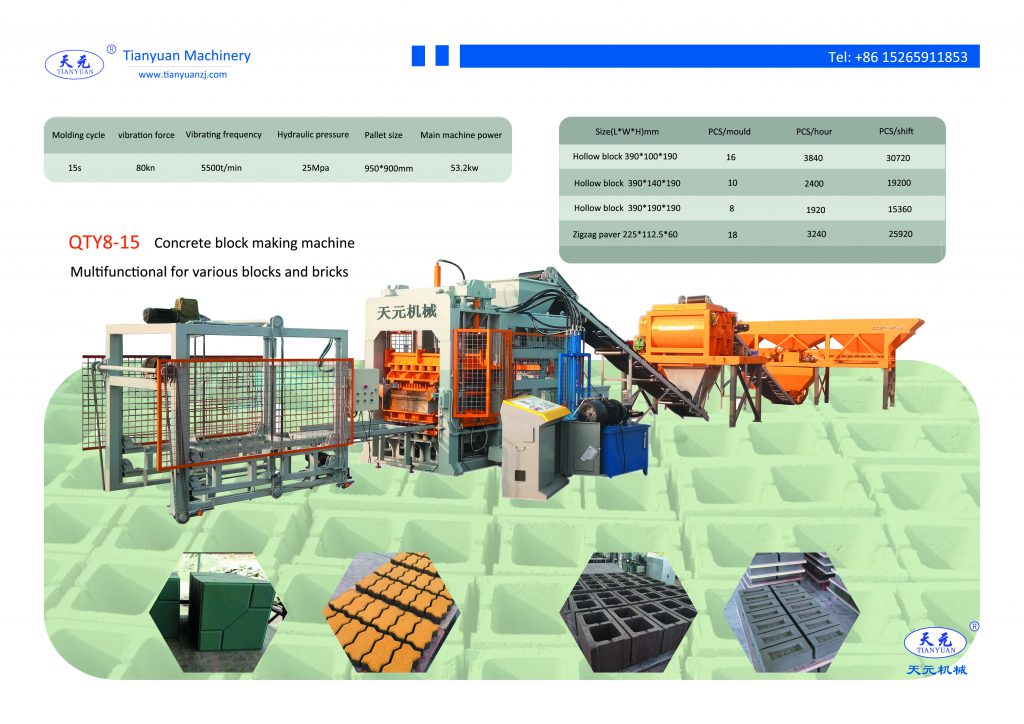

- Automatic Concrete hollow block making machine production line QTY8-15 for sale

1. Automatic hollow block making machine with PLC control system.

2. Automatic hollow block making machine Hydraulic pressure to supply strong support for high output.

3. Automatic hollow block making machine Multi-function, change different moulds for different sized hollow blocks, solid bricks,color pavers,interlocking blocks, curbs,etc.

4. Automatic hollow block making machine Raw materials could be cement,sand,crushed stone,fly ash,slag,cinder,caramsite concrete,etc.

- feature of product:

(1) It adopts vertical directional vibration and pressure forming of the mold box, multi-axis rotary feeding device, and arch-breaking cloth rake. The molding cycle is short, the production efficiency is high, the block quality is high, the density is high, and the dimensions are accurate.

(2) The pressure head uses a synchronized box to vibrate and pressurize. The high pressure (up to 100T) structure ensures the high strength and compactness of the blocks; a speed-increasing cylinder is used to increase the speed to ensure the molding cycle.

(3) The guide column is made of special steel, and the surface is chromium-plated with good torsion resistance and wear resistance. The four-rod guide method and long guide bearing ensure the accurate movement of the indenter and the mold; special devices are used in the moving parts to facilitate Lubricated and not easy to wear.

(4) The frame uses structural steel and special welding technology to ensure the rigidity and vibration resistance of the equipment.

(5) The designed storage and distribution system: ensures the accuracy of material supply, reduces the uneven density of materials under the action of internal pressure and other external factors, which affects the amount of material supplied, and ensures that materials are delivered immediately after use and the amount of material is accurate. Make the product density consistent.

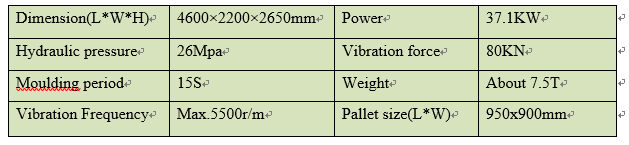

- Block machine specifications:

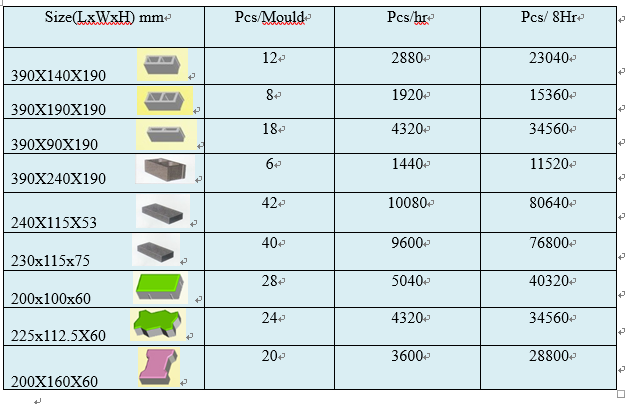

- Capacity reference: